Q:

The software reports an error message "Abnormal ink stack". What should I do?

Analysis:

When the machine is reset and initialized or cleaned, the ink stack cannot rise or fall normally,

and at the same time, the software prompts "Abnormal ink stack".

This situation usually may have several reasons:

1. The DC24V power supply part of the entire machine is abnormal

2. The mechanical part of the ink stack is abnormal and the movement is not smooth

3. Abnormal ink stack sensor or loose wire plug

4. Abnormal motor of the ink stack or loose wire plug

A:

Step 1: Check whether the DC24V power supply of the machine is normal

Check whether the indicator light of the DC24V power supply section of the machine is normal, and at the same time, check whether the led lighting on the printer table surface is normal.

If the led lighting on the printer's countertop does not light up either, it is usually because there is an abnormality with the DC24V power supply of the entire machine, and the power supply part needs to be replaced.

Step 2: Check whether the mechanical parts of the ink stack move smoothly

Turn off the power of the printer, manually rotate the handle of the ink stack, and check if it rises and falls smoothly or if there is a lot of resistance

If there is a lot of resistance when manually rotating the knob, refer to the following video to lubricate each moving part of the ink stack

(It is best to use screw-specific lubricating oil or grease.)

Step 3: Check whether the sensor of the ink stack is working properly

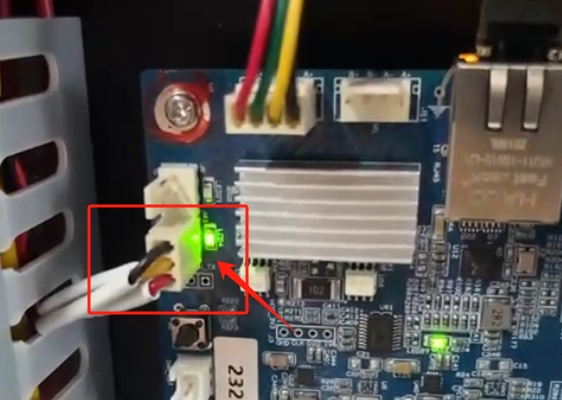

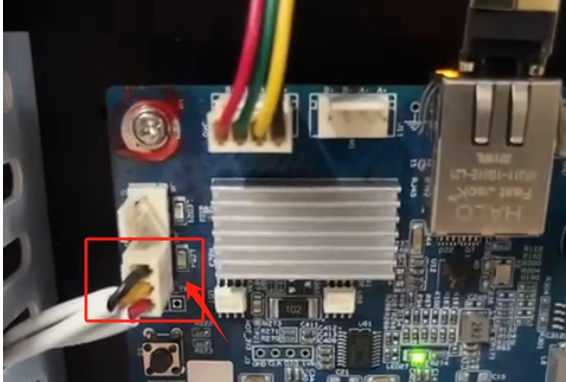

Use an opaque material to sense the sensor and check whether the indicator light corresponding to the sensor plug position on the motherboard changes

Under normal circumstances, when the sensor has no material to sense, the indicator light corresponding to the sensor plug position on the motherboard should remain constantly on.

Under normal circumstances, when the sensor senses a material,

the indicator light corresponding to the sensor plug position on the motherboard should always be off.

The operation video is as follows:

If the indicator light corresponding to the sensor is not normal, it might be that the sensor plug is loose. Try reinserting and unplugging the plugs at both ends, or the sensor is abnormal and needs to be replaced.

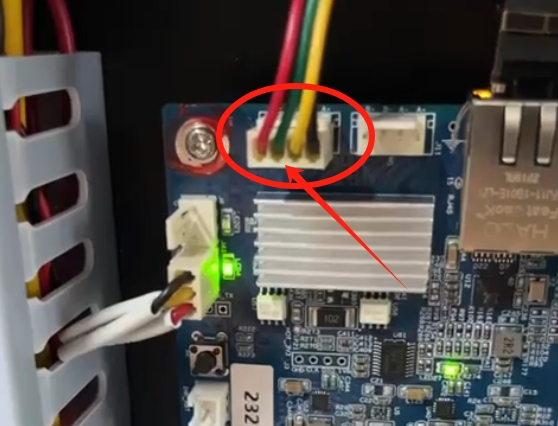

Step 4: Check whether the motor of the ink stack is working properly

Behind the ink stack, follow the motor to find the middle connection plug. The plug has four pins. Check if there is any loosening or detachment. Reinsert and unplug them to connect.

At the same time, follow the plug to find the plug where the ink stack motor is connected to the mainboard. It also has 4 pins. Check if there are any loose or fallen pins. Reinsert and unplug them to connect.

If all the above checks are normal, there may be an abnormality inside the motor plug or wire. The ink stack motor and wire need to be replaced.

Note: If the problem cannot be solved through the above methods, it is recommended to contact our relevant engineers for professional services.

If you have any questions, please contact the relevant personnel.

Add: No.6-2, Jinhua Zhong Road,Zhongshan

Tel: 86-760-88667090

Fax: 86-760-88667096

E-mail: market2@titanjet.com.cn

betty@titanjet.com.cn

he@titanjet.com.cn